VERTICAL ACCUMULATOR

Wide range of Vertical Accumulator for LASER or HF tube mills, even for existing lines.

BED ROLLER

Olimpia 80 offers bead rolling machines for the inside removal of the weld bead that can guarantee an high finish quality and the greatest stability. This bead roller is suitable for Tig and Laser welded tubes, with inside diameter fron 14 mm to 220 mm. Tube speed: max. 10m/min.

NEW MAGNETIC BEAD ROLLER

This equipment, specifically designed for laser welding Tube Mill, gives the advantage of no mechanical connections between mandrel and any external support: the wire rope moving the mandrel in the traditional hydraulic system can be totally eliminated.

The internal mandrel works thanks to the magnetic field generated by a permanent magnet sliding on rails in an alternate rectilinear motion. This permits also the consequent reduction of the minimum inside-rolling diameter.

CUT OFF EQUIPMENT

Olimpia 80 makes different types of in-line tube cutting machines studied for all kind of materials and production speeds.

COLD SAW CUT OFF with positioning of the cutting head at 45°. This equipment is especially suitable for Laser and Tig production lines and allows high precision and good tube end finishing.

CUTTING MACHINE BY BAND SAW for tubes up to 114 mm OD.

CUT OFF EQUIPMENT

DOUBLE BLADE FLYING CUT OFF

This cutting machine, especially designed for large pipes.

The machines works with 2 blades, mounted on slides and placed on a rotating support, penetrate into the tube with material removal and make the complete product cutting by means of the support rotation.

Tube is hydraulically clamped and the complete cutting group is mounted on a sliding carriage which is complete with electronic movement device that assure a cutting precision of +/- 1 mm.

A PLC controls the machine operations and automatically determines, fixing some data regarding the product and the used blades, the carriage and blade speed and the blade position, making the cutting programming and process fast and easy.

Double blade cut off for 16” tube mill.

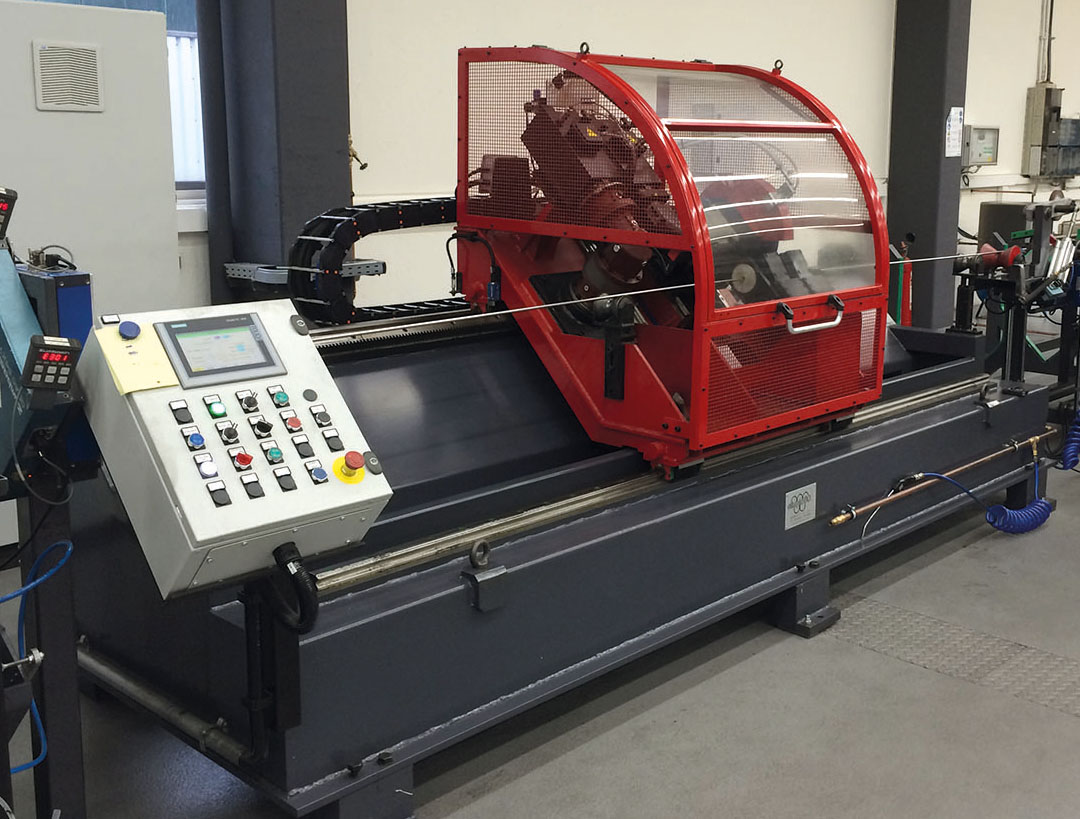

DISK SAW CUTTING MACHINES FOR HIGH FREQUENCY MILLS

These cutting equipment are design for cutting tubes at high production speeds.

An automatic control system allows to optimize blade positioning according to the tube diameter and thickness, setting the speed of feeding and rotation of the blades.

This system is able to optimize and increase the number of cuts.

Friction saw flying cutting machine.

Flying cut off with friction saw.